The Major Advantages Of Rapid Prototyping

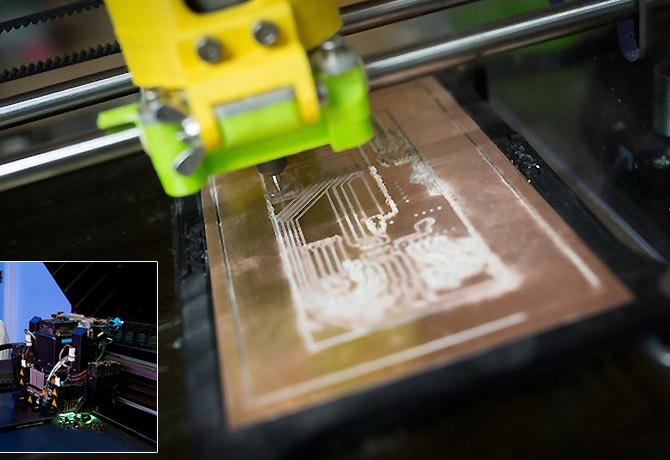

Rapid prototyping can be characterized as a displaying method which improves and accelerates the advancement of new items. It is a cycle that utilizes PC helped apparatuses and methods, for example, 3D printing and sound system lithography to make physical item models for creation tooling and investigation. The cycle can be extremely useful to item architects, segment providers and even makers and accompanies various points of interest to all who decide to utilize the procedure.

- It spares time

Rapid prototyping dispenses with constantly that is needed to create designs, exceptional instruments and forms for traditional displaying. The exact model is made rapidly accessible for highlight, ease of use, execution and structure testing utilizing the procedure something that would have set aside a long effort to accomplish utilizing the regular technique. This is on the grounds that the cycle is to a great extent computerized and originators can even change items quicker and before large scale manufacturing. You would now be able to get your items in the market quick and in front of your rivals.

- It opens up development openings

Another significant bit of leeway of the rapid prototyping factory is that creators have the opportunity to make models that are perplexing in surfaces and formed without agonizing over precise creation. This is something that would have been inconceivable or exceptionally repetitive to accomplish with traditional prototyping as a result of limitations in physical segments and prototype tooling. Imagination is taken to the following level by rapid prototyping method.

- It decreases costs

This method diminished item advancement costs in light of the fact that no exceptional apparatuses are required for each new item. It is a cycle that depends on printing hardware and CAD all the time along these lines lessening costs. There is additionally decreased work thinking about that the cycle is computerized and an organization does not thusly need having an enormous staff group to complete the work. The waste expenses are likewise limited by the cycle in light of the fact that there is no material chipping that happens to get a completed model utilizing the traditional procedures.

- It offers simpler representation

3D molds are sensible and simple to present to customers or partners on account of simple review, everything being equal, and points that issue. With this representation, the improvement program is affirmed quick since it is simpler for everybody required to comprehend the item all things considered. It is a lot simpler to examine the item when it is conceivable to contact it and view all parts contrasted with depending on a printed variant of a similar item. Significant changes should likewise be possible to improve the item.

- It brings down the dangers of mistakes

Basic item blunders can be very exorbitant and rapid prototyping dispenses with the odds of something like this incident. The creation group can recognize issues and issues and make quick changes before large scale manufacturing happens. It guarantees that the completed items are entirely done. This method likewise permits customization of the items to suit customer needs and inclinations.

Comments are Closed